Can Power Tap help simplify the connection and control of high-power devices?

2024-11-291. Advantages of Power Tap in simplifying the connection of high-power devicesPower Tap has multiple high-power sockets ...

Provide you with the later enterprise and industry news.

View More

View More

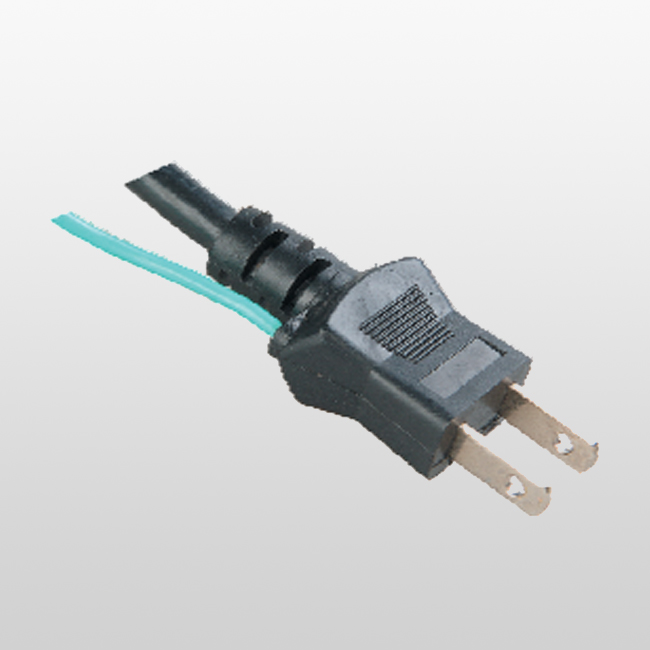

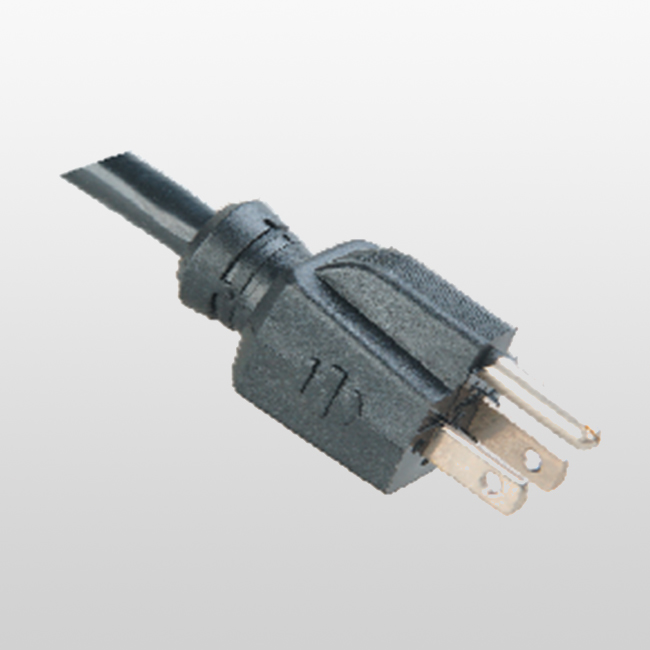

As China Wholesale Power cord with CCC Suppliers, Yuyao Hengyue Electric Co., Ltd. is a large-scale enterprise specializing in the manufacture of conversion sockets, plugs and power cords all over the world.